Copper pipe sizing is critical for ensuring efficient and safe fluid flow in plumbing and HVAC systems. A copper pipe size chart provides detailed measurements, including nominal pipe size (NPS), outside diameter (OD), and inside diameter (ID), to help select the right tubing for specific applications. Proper sizing ensures optimal performance, prevents pressure drops, and minimizes risks of corrosion or failure. Always refer to manufacturer guidelines and industry standards for accurate sizing recommendations.

1.1 Importance of Proper Pipe Sizing

Proper copper pipe sizing is essential for maintaining optimal pressure, flow rate, and system efficiency; Incorrect sizing can lead to pressure drops, reduced performance, and increased energy costs. Oversized pipes may result in higher material and installation costs, while undersized pipes can cause material degradation and leaks. Ensuring the right pipe size prevents corrosion risks and guarantees long-term system reliability. Referencing a copper pipe size chart helps determine the ideal dimensions for specific applications, ensuring safety and efficiency in plumbing and HVAC systems.

1.2 Overview of Copper Pipe Applications

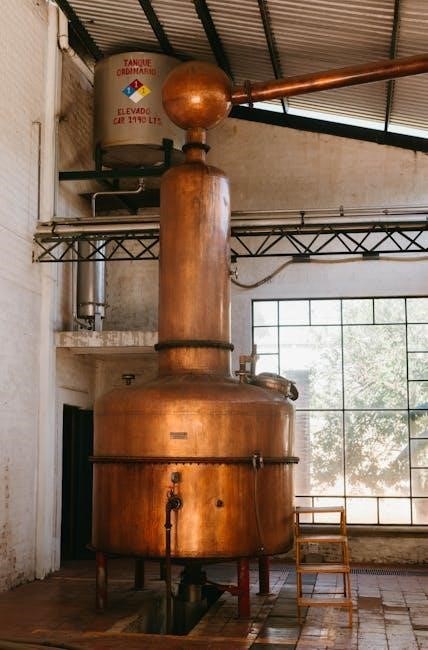

Copper pipes are widely used in residential, commercial, and industrial settings due to their durability and excellent heat conductivity. They are commonly employed in plumbing systems for water distribution, HVAC systems for heating and cooling, and refrigeration systems for efficient thermal transfer. Copper tubing is also used in medical gas systems and fire suppression due to its reliability and resistance to corrosion. The versatility of copper pipes makes them a preferred choice across various industries, supported by detailed size charts for precise application suitability.

Key Factors Influencing Copper Pipe Sizing

Pressure, temperature, and flow rate are key factors in sizing copper pipes to ensure system efficiency and safety. Always consult manufacturer guidelines for precise specifications.

2.1 Pressure Requirements

Pressure requirements are a critical factor in copper pipe sizing, as they determine the system’s ability to handle fluid flow without leakage or damage. Undersized pipes may fail under high pressure, while oversizing can lead to unnecessary costs. The maximum allowable pressure depends on the pipe’s nominal pipe size (NPS) and wall thickness. Always consult a copper pipe size chart to ensure the selected tubing meets the system’s pressure demands, ensuring safety and efficiency in plumbing and HVAC applications.

2.2 Temperature Considerations

Temperature significantly impacts copper pipe sizing, as thermal expansion and material durability vary with heat. Extreme temperatures can cause copper to expand or degrade, affecting system performance. High-temperature applications, such as HVAC systems, require thicker-walled pipes to maintain integrity. Conversely, lower temperatures may demand specific sizing to prevent freezing or pressure fluctuations. Referencing a copper pipe size chart ensures compatibility with temperature conditions, optimizing system reliability and longevity in both hot and cold fluid transfer scenarios.

2.3 Flow Rate and Velocity

Flow rate and velocity are critical factors in copper pipe sizing, ensuring efficient fluid transport without erosion or pressure loss. Higher flow rates require larger diameters to maintain optimal velocity, preventing turbulence and noise. Excessive velocity can lead to pipe wear, while insufficient flow rates reduce system performance. A copper pipe size chart helps determine the ideal diameter and wall thickness to balance flow rate and velocity, ensuring smooth operation in plumbing, HVAC, and industrial systems. Proper sizing enhances durability and operational efficiency.

Types of Copper Pipes and Their Uses

Copper pipes are categorized into types like K, L, and M, each designed for specific applications. Type K is thick-walled for high-pressure uses, while Type L and M are thinner, suitable for residential plumbing and HVAC systems. Specialized types, like those used in refrigeration, offer unique properties for distinct industrial needs, ensuring durability and reliability across various installations.

3.1 Type K Copper Pipe

Type K copper pipe is the thickest and most durable option, designed for high-pressure and high-temperature applications. Commonly used in HVAC systems and industrial settings, it offers superior strength and resistance to corrosion. Its robust construction makes it ideal for underground burial, ensuring long-lasting performance. This versatility and reliability make Type K a preferred choice for demanding environments where durability is crucial.

3.2 Type L Copper Pipe

Type L copper pipe is a popular choice for residential and commercial plumbing due to its optimal balance of durability and affordability. It has a thicker wall than Type M but thinner than Type K, making it suitable for standard water distribution and gas lines. Its flexibility and resistance to corrosion ensure long-term reliability. Type L is widely used for both hot and cold water systems, offering a reliable solution for typical plumbing needs without the higher cost of heavier-duty options.

3.3 Type M Copper Pipe

Type M copper pipe is the thinnest and most lightweight option among standard copper tubing types. It is ideal for low-pressure applications, such as residential water supply lines, due to its thinner walls compared to Type L. Type M is cost-effective and easier to install, making it a practical choice for projects where weight and material cost are considerations. However, its thinner construction makes it less suitable for high-pressure or industrial settings, where heavier-duty pipes are required for durability and safety.

3.4 Other Specialized Types

Beyond the standard types, specialized copper pipes cater to specific applications. Type ACR (Air Conditioning and Refrigeration) is designed for high-pressure refrigeration systems, offering superior strength and durability. Type DWV (Drain, Waste, and Vent) is used in drainage systems due to its resistance to corrosion and ability to handle gases. Additionally, there are refrigeration-grade copper pipes, such as those sized 3/16″ to 1″, which are tailored for HVAC and refrigeration systems, ensuring efficient heat transfer and system performance in demanding environments.

Copper Pipe Size Chart Details

Copper pipe size charts detail nominal pipe size (NPS), outside diameter (OD), inside diameter (ID), and wall thickness. These measurements are crucial for selecting the right tubing for specific applications, ensuring proper flow rates, and meeting pressure requirements. The charts also highlight the relationship between pipe sizes and their intended uses, helping users make informed decisions for plumbing, HVAC, and industrial systems.

4.1 Nominal Pipe Size (NPS) vs. Actual Diameter

Nominal Pipe Size (NPS) is a designation that approximates the inside diameter of a pipe, differing from its actual diameter. While NPS is not the exact measurement, it provides a standardized reference for pipe sizing. The actual diameter, including both the outside (OD) and inside (ID), varies based on wall thickness and pipe type. Copper pipe size charts clarify these distinctions, ensuring precise selections for installations, whether in residential or industrial settings. Always refer to these charts for accurate sizing to avoid system inefficiencies or failures.

4.2 Outside Diameter (OD) and Inside Diameter (ID)

The outside diameter (OD) and inside diameter (ID) of copper pipes are critical measurements for proper system design. While the OD remains consistent for a given pipe size, the ID varies based on wall thickness. Copper pipe size charts provide precise OD and ID values, ensuring compatibility with fittings and optimal flow rates. Understanding these dimensions is essential for selecting the right tubing for specific applications, as outlined in the copper pipe size chart PDF, which details standard sizes and wall thicknesses for accurate installations.

4.3 Wall Thickness and Its Significance

Wall thickness is a critical factor in copper pipe sizing, as it directly impacts durability, flow capacity, and resistance to pressure and corrosion. Thicker walls, such as in Type K copper pipes, offer greater strength and longevity, making them ideal for high-pressure or industrial applications. Thinner walls, like in Type M pipes, are more cost-effective and suitable for residential use. Proper wall thickness ensures system performance, safety, and cost efficiency, as detailed in copper pipe size charts for accurate material selection and installation.

Applications of Copper Pipe Sizing

Copper pipe sizing is essential for residential plumbing, commercial systems, HVAC, and refrigeration. Proper sizing ensures efficient fluid flow and heat transfer, meeting system requirements effectively.

5.1 Residential Plumbing Systems

In residential plumbing, copper pipes are widely used due to their durability and reliability. Proper sizing ensures adequate water flow and pressure, preventing issues like low water pressure or excessive noise. Common applications include water supply lines, heating systems, and gas lines. A copper pipe size chart helps determine the appropriate diameter for each use case, ensuring system efficiency and longevity. Correct sizing also minimizes the risk of corrosion and leaks, enhancing overall performance and safety in home plumbing systems.

5.2 Commercial and Industrial Systems

In commercial and industrial settings, copper pipes are essential for handling heavy-duty applications, including HVAC, refrigeration, and large-scale fluid distribution. Proper sizing ensures systems operate efficiently under high pressure and flow rates. Larger diameters, such as 1/2-inch or 3/4-inch, are often used to meet demand. Correct sizing prevents pressure drops, reduces energy costs, and ensures system longevity. Referencing a copper pipe size chart is crucial for selecting the right tubing to meet specific industrial requirements and safety standards, ensuring reliable performance in demanding environments.

5.3 HVAC and Refrigeration Systems

Copper pipes are widely used in HVAC and refrigeration systems due to their excellent heat transfer properties and durability. Proper sizing is crucial to ensure efficient cooling and heating. Common sizes like 3/16-inch and 1/2-inch are often specified for refrigerant lines, while larger diameters handle fluid distribution. Incorrect sizing can lead to reduced system performance, increased energy costs, and potential equipment damage. Always consult a copper pipe size chart to match tubing dimensions with system requirements, ensuring optimal efficiency and reliability in HVAC and refrigeration applications.

Safety and Handling Guidelines

Handle copper pipes with care to avoid scratches and damage. Store them in a dry, clean environment to prevent corrosion. Always follow safety precautions during cutting and soldering to avoid injuries and fires. Proper handling ensures longevity and safety in plumbing and HVAC installations. Dispose of scrap copper responsibly, adhering to environmental regulations.

6.1 Proper Handling Techniques

Proper handling of copper pipes is essential to prevent damage and ensure safety. Always wear gloves to protect against sharp edges and use a pipe cutter or saw for clean cuts. Avoid dragging pipes across surfaces to prevent scratching. Store copper pipes in a dry, clean environment, away from direct sunlight and moisture. Use cardboard or wooden separators for stacked pipes to prevent denting. Handle pipes securely during transportation to avoid bending or kinking; Use padded tools to grip pipes firmly without causing damage. Proper handling techniques ensure the integrity of the copper pipes and promote a safe working environment.

6.2 Safety Precautions During Installation

During copper pipe installation, safety is paramount. Always wear protective gear, including safety goggles and gloves, to shield against debris and chemicals. Ensure the work area is well-ventilated to avoid inhaling soldering fumes. Keep a fire extinguisher nearby when soldering or brazing. Turn off water and gas supplies before starting work. Use proper lifting techniques to prevent injury from heavy pipes. Follow manufacturer instructions for soldering compounds and fluxes. Never leave open flames or sparks unattended. Adhering to these precautions minimizes risks and ensures a secure installation process.

6.3 Environmental Considerations

Copper pipe installations must consider environmental impact. Copper is recyclable and durable, reducing long-term resource consumption. Proper disposal of scraps and materials is essential to prevent contamination. Use eco-friendly soldering compounds to minimize toxic emissions. Ensure systems are designed for efficiency to reduce water and energy waste. Regular maintenance helps prevent leaks, conserving resources. Adhering to environmental guidelines promotes sustainable practices and minimizes ecological footprint, aligning with global conservation efforts and responsible resource management.

Installation Best Practices

Proper installation requires using the right tools, following manufacturer guidelines, ensuring clean connections, and testing the system for leaks and pressure stability.

7.1 Tools Required for Copper Pipe Installation

Essential tools for copper pipe installation include a tubing cutter, propane torch, flux, solder, pipe bender, and fittings. A pipe cutter ensures clean, precise cuts, while a propane torch is used for soldering and brazing. Flux prevents oxidation, ensuring strong connections. A pipe bender helps shape tubing without kinking. Always use high-quality tools to maintain system integrity and safety, following manufacturer guidelines for optimal results.

7.2 Joining Techniques (Soldering, Brazing, etc.)

Copper pipe joining techniques like soldering and brazing ensure leak-proof connections. Soldering uses a torch to melt solder, filling gaps between pipe and fittings, while brazing uses a higher-temperature alloy for stronger bonds. Proper preparation, including cleaning and applying flux, is crucial. These methods are widely used in plumbing and HVAC systems for durability and reliability. Always follow safety guidelines and manufacturer recommendations for optimal results and long-lasting connections.

7.3 Testing the System After Installation

Testing the system after installation is crucial to ensure all components function correctly and safely. Conduct thorough pressure tests to verify there are no leaks and that the system operates within the designed pressure range. Perform visual inspections of all connections and joints to ensure they are secure and properly sealed. Use tools like pressure gauges to monitor the system’s performance accurately. Ensure compliance with safety standards and manufacturer guidelines for optimal results. Proper testing guarantees the reliability, efficiency, and safety of the copper piping system.

Maintenance and Repair Tips

Regular inspection and cleaning are essential to maintain copper pipe systems. Inspect for leaks, corrosion, or damage, and address issues promptly to prevent further escalation. Clean corroded areas and replace damaged sections to extend system lifespan and ensure efficiency.

8.1 Regular Inspection and Cleaning

Regular inspection and cleaning of copper pipes are crucial for maintaining system efficiency and longevity. Inspect pipes for signs of corrosion, leaks, or mineral buildup. Clean corroded areas using mild abrasives or chemical solutions to prevent damage. Additionally, flush the system periodically to remove debris and sediment, ensuring optimal flow rates. Addressing issues early prevents costly repairs and extends the lifespan of the copper piping system. Regular maintenance also enhances safety by reducing the risk of sudden failures.

8.2 Troubleshooting Common Issues

Troubleshooting common issues in copper piping involves identifying leaks, corrosion, and flow restrictions. Leaks often occur at joints due to improper soldering or wear. Corrosion may result from incompatible materials or water chemistry. Flow restrictions can stem from mineral buildup or incorrect pipe sizing. Use a copper pipe size chart to verify if the pipe diameter matches system requirements. Addressing these issues promptly prevents further damage and ensures reliable system performance. Regular maintenance helps mitigate these problems, keeping the system operational and efficient.

8.3 Repairing Damaged or Corroded Pipes

Repairing damaged or corroded copper pipes involves assessing the extent of the damage. For minor leaks, applying epoxy or soldering may suffice. Corroded sections often require replacement to ensure system integrity. Use a copper pipe size chart to verify the correct diameter and wall thickness for replacements. Clean the area around the damage thoroughly before applying any repair method. For severe corrosion, replacing the entire section is recommended. Always ensure materials are compatible with the system to prevent future issues and maintain optimal performance.

Common Mistakes to Avoid

Avoiding common mistakes in copper pipe sizing ensures system efficiency and safety. Incorrect sizing, ignoring pressure ratings, and poor installation practices can lead to leaks, corrosion, and failure. Always refer to copper pipe size charts and manufacturer guidelines to select the right tubing for your application. Neglecting these steps can result in costly repairs and compromised performance. Proper planning and adherence to standards are essential for long-term reliability.

9.1 Incorrect Pipe Sizing

Incorrect copper pipe sizing can lead to reduced system efficiency, increased energy costs, and potential failures. Undersized pipes may cause pressure drops, noise, and overheating, while oversizing can result in higher material costs and inefficient fluid flow. Always consult a copper pipe size chart to ensure proper sizing based on flow rate, pressure, and temperature requirements. Ignoring these factors can lead to system malfunctions and premature wear. Proper sizing is crucial for optimal performance and longevity in plumbing and HVAC systems.

9.2 Improper Installation Practices

Improper installation of copper pipes can lead to leaks, corrosion, and system failures. Common mistakes include incorrect soldering, insufficient flux application, and poor joining techniques. Neglecting to properly clean and deburr pipes before soldering can result in weak joints. Overheating during soldering can damage the pipe or fittings. Additionally, failing to follow manufacturer guidelines for brazing or soldering temperatures can compromise the integrity of connections. Always use proper tools and techniques to ensure a durable and leak-free installation that meets safety and performance standards.

9.3 Neglecting Maintenance

Neglecting regular maintenance can lead to premature wear, corrosion, and leaks in copper piping systems. Failing to inspect pipes for signs of damage or corrosion allows small issues to escalate into major problems. Over time, mineral buildup and debris can restrict flow, reducing system efficiency. Routine cleaning and inspection are essential to identify and address potential issues early. Ignoring maintenance can result in costly repairs and system downtime, emphasizing the importance of proactive care for long-term reliability and safety.

Resources and References

Access official copper pipe size charts, manufacturer guides, and online calculators for precise sizing and installation details, ensuring compliance with industry standards.

10.1 Where to Find Copper Pipe Size Charts

Copper pipe size charts are available in manufacturer guides, official publications, and online resources. They are often provided as downloadable PDFs on manufacturer websites and industry standard portals. Major plumbing and HVAC suppliers also offer detailed size charts tailored to specific applications. Additionally, trade organizations and engineering associations publish standardized pipe sizing references for easy access. These resources ensure accurate sizing for various systems and compliance with safety regulations.

10.2 Recommended Manuals and Guides

For accurate copper pipe sizing, consult manuals like the ASHRAE Handbook, ASTM standards, and ANSI guidelines. The Copper Development Association publishes comprehensive guides, and manufacturer-specific manuals provide detailed sizing charts and material specifications. These resources ensure compliance with safety and performance standards. They are essential for engineers, contractors, and DIYers to make informed decisions. Always refer to the latest editions for updated information and industry best practices.

10.3 Online Tools and Calculators

Utilize online tools and calculators for precise copper pipe sizing. Websites like the Copper Development Association and engineering tool platforms offer interactive calculators to determine optimal pipe sizes based on flow rate, pressure, and temperature. These tools provide instant results, reducing manual calculation errors. They are invaluable for engineers, contractors, and DIYers to ensure system efficiency and safety. Many resources also include downloadable charts and guides for offline use, enhancing accessibility and convenience for various projects and applications.