An 11-pin relay wiring diagram is a detailed visual guide for engineers and technicians, explaining circuit connections and functions. It simplifies wiring complex relays, ensuring proper setup and safety. These diagrams are crucial for understanding voltage, current, and pin configurations, making them indispensable in automotive and industrial automation projects.

Overview of Relays in Electrical Systems

Relays are essential components in electrical systems, acting as electrically controlled switches. They enable a low-power signal to control a high-power circuit, making them indispensable in various applications. Relays consist of an electromagnetic coil and movable contacts, which connect or disconnect circuits when the coil is energized. This functionality allows for precise control over power distribution, ensuring efficient and safe operation. In automotive, industrial, and home appliances, relays play a crucial role in managing loads, isolating circuits, and reducing power consumption. Understanding relays is fundamental for diagnosing and repairing electrical systems, as they often serve as the interface between control systems and high-current devices. Their versatility and reliability make them a cornerstone in modern electrical engineering, ensuring systems operate smoothly and safely under various conditions.

Importance of Wiring Diagrams for 11-Pin Relays

Wiring diagrams for 11-pin relays are essential for understanding and installing complex electrical circuits. They provide a clear visual representation of pin functions, connections, and voltage requirements, ensuring proper setup and operation. Without these diagrams, identifying the correct pins for power, control, and load connections becomes challenging, increasing the risk of errors. They also act as a reference for troubleshooting issues, such as faulty connections or misconfigured circuits. By following a wiring diagram, engineers and technicians can avoid common mistakes, ensuring safety and reliability in automotive, industrial, and automation systems. These diagrams are particularly useful for beginners, as they simplify the process of working with multi-pin relays. Overall, wiring diagrams are indispensable tools for efficient and accurate relay installation and maintenance.

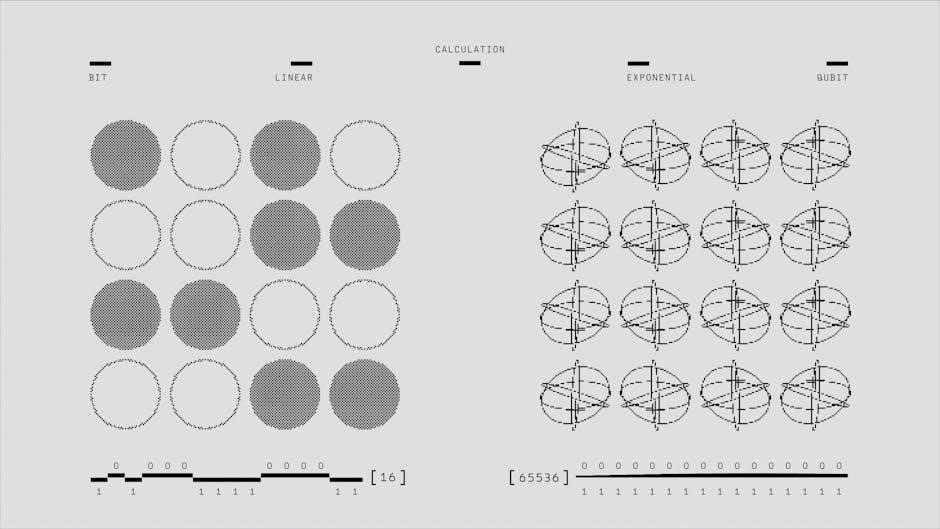

Understanding the 11-Pin Relay Configuration

The 11-pin relay configuration defines the arrangement and functions of each pin, enabling precise control over electrical circuits. It specifies connections for voltage, current, and control signals, ensuring proper operation.

Pin Configuration and Functions

The 11-pin relay features a standardized configuration, with each pin designated for specific functions. Pins 1 and 2 typically serve as the coil terminals, responsible for activating the relay. Pins 3 and 4 are usually the normally open (NO) and normally closed (NC) contacts for the first circuit, while pins 5 and 6 handle the second circuit’s NO and NC connections. Pins 7 and 8 often function as auxiliary contacts, providing additional control options. Pins 9 and 10 may act as voltage supply terminals for the load circuit, with pin 11 sometimes reserved for a ground connection. Understanding these roles is crucial for proper wiring. However, configurations can vary by manufacturer, so consulting the specific wiring diagram for your relay is essential to ensure accurate connections and avoid malfunctions.

Common Applications of 11-Pin Relays

11-pin relays are widely used in automotive systems, industrial automation, and HVAC controls due to their versatility and reliability. They are commonly found in cooling fan circuits, where they control the operation of fans based on temperature inputs. In industrial settings, these relays are used for motor control, solenoid activation, and power distribution. Additionally, they are integral in lighting systems, where they manage dimming or switching operations. Their high current-handling capacity makes them suitable for heavy-duty applications, such as powering pumps or compressors. Automotive applications include fuel pumps, ABS systems, and windshield wipers. Their compact design and multi-pin configuration allow for complex wiring configurations, ensuring precise control in demanding environments. Whether in vehicles or industrial machinery, 11-pin relays are essential for reliable and efficient circuit management.

Reading and Interpreting the Wiring Diagram

Understanding symbols and abbreviations is crucial for interpreting 11-pin relay wiring diagrams. Recognizing these elements helps technicians identify connections and ensure proper wiring, minimizing errors during installation.

Understanding Symbols and Abbreviations

Wiring diagrams for 11-pin relays use specific symbols and abbreviations to represent components and connections. Common symbols include circles for relays, lines for wires, and arrows for current flow. Abbreviations like “NO” (Normally Open) and “NC” (Normally Closed) indicate contact states. Understanding these symbols is crucial for interpreting the diagram accurately.

Each pin on the relay is labeled with a number and function, such as “COIL A1” or “NO1.” These labels help identify how power and control circuits connect. Diagrams may also use color coding to differentiate between control and power circuits, enhancing readability. Consistency in symbols ensures that the wiring process remains clear and error-free. Always refer to the legend or key provided with the diagram for precise interpretations. Proper understanding of these elements is essential for safe and correct wiring of the 11-pin relay.

Identifying Key Components in the Diagram

In an 11-pin relay wiring diagram, identifying key components is essential for proper installation and operation. Start by locating the coil pins, typically labeled as terminals A1 and A2, which energize the relay. Next, identify the normally open (NO) and normally closed (NC) contacts, labeled as B1, B2, and 87, 87a, respectively. Auxiliary contacts, if present, are marked separately. The diagram will also show the common terminal (30) and the load terminals (87 and 87a). Look for symbols representing power sources, loads, and control circuits. Pay attention to labels and color coding, which differentiate between the control circuit (lower current) and the power circuit (higher current). Understanding these components ensures accurate wiring and prevents failures. Always cross-reference with the relay’s datasheet to confirm pin functions, as configurations can vary by manufacturer and relay type.

Step-by-Step Wiring Guide

Start by identifying the 11-pin relay’s configuration and matching it to your circuit. Connect the control circuit to activate the relay, then link the power circuit to the load. Ensure proper grounding for safety and stability.

Preparing for Wiring

Before starting the wiring process, gather all necessary tools and materials. Ensure you have the 11-pin relay, a wiring diagram, multimeter, wire strippers, and appropriate connectors. Verify the relay’s specifications match your application to avoid compatibility issues. Inspect the relay pins for damage or corrosion, as this can disrupt the circuit. Familiarize yourself with the wiring diagram, noting the control and power circuits. Plan the wiring layout to minimize cross-connections and ensure proper insulation. Use a multimeter to test the relay’s coil resistance and ensure it matches the datasheet. Identify a suitable power source and ensure all safety precautions are in place. Grounding the system correctly is essential to prevent electrical hazards. Double-check the wiring sequence to avoid short circuits. Finally, test the relay in a controlled environment before integrating it into the main circuit to ensure proper functionality.

Connecting the Control Circuit

Connecting the control circuit for an 11-pin relay involves linking the necessary components to activate the relay’s coil. Start by identifying the coil pins (typically pins 1 and 2) and connect them to the power supply and ground. Pin 3 usually serves as the trigger input, requiring a signal from a switch or controller to energize the coil. Ensure the wiring matches the relay’s voltage rating (e.g., 24V DC) to avoid damage. Use appropriate gauge wires and connectors for reliable connections. Always de-energize the circuit before wiring to prevent electrical shocks or component damage. Double-check the wiring against the diagram to confirm pin assignments. Once connected, test the circuit to ensure the relay activates when the control signal is applied. Proper wiring ensures smooth operation and prevents malfunctions. Follow safety guidelines and use a multimeter to verify connections before powering up the system.

Connecting the Power Circuit

Connecting the power circuit in an 11-pin relay setup involves linking the relay to the load and power source. Identify the pins designated for the power supply and load connections, typically labeled as “30” and “87” or similar. Use appropriately sized wires to connect the power source to the relay’s input pins. Ensure the load, such as a motor or light, is connected between the relay’s output pins and ground. Double-check the polarity to prevent damage. For high-current applications, install a fuse or circuit breaker near the power source. Use heat-shrink tubing or soldering for secure connections. Always refer to the wiring diagram to confirm pin assignments. Testing the circuit with a multimeter before applying power is recommended to verify continuity and isolation. Properly securing wires with zip ties or clips ensures reliability and safety over time. Follow safety guidelines to avoid electrical shock or short circuits.

Testing the Relay Circuit

Testing the relay circuit is essential to ensure proper functionality after wiring. Begin by verifying the power supply to the control and load circuits. Use a multimeter to measure voltage at the relay pins, ensuring it matches the specified requirements. Activate the control circuit (e.g., switch or signal) to energize the relay coil. Listen for the audible “click” indicating the relay has activated. Check the load circuit for power using a test light or multimeter. Measure resistance across the normally open (NO) and normally closed (NC) contacts to confirm they switch correctly. If the relay fails to activate, inspect connections for shorts or opens and ensure proper ground. Consult the wiring diagram for pin-specific voltage levels. Testing ensures the relay operates as intended, preventing system malfunctions. Always disconnect power before performing detailed tests to avoid electrical hazards.

Troubleshooting Common Issues

Common 11-pin relay issues include short circuits, open circuits, and incorrect pin connections. Diagnosing involves checking connections, verifying power supply, and testing coil resistance with a multimeter properly.

Diagnosing Relay Failures

Diagnosing relay failures is critical for maintaining reliable electrical systems. Common issues include the relay not activating, stuck contacts, or complete circuit disconnection. Start by checking the power supply and control signals using a multimeter. Verify if the control circuit is providing the correct voltage to the relay coil. If the coil is energized but the contacts fail to switch, inspect for worn or corroded terminals. Use the 11-pin relay wiring diagram to trace connections and identify potential short circuits or open lines. Listen for the relay’s clicking sound to confirm coil activation. If the relay fails to click, it may indicate a faulty coil or insufficient voltage. Testing each pin’s connectivity ensures proper operation. Regular inspection and cleaning of contacts can prevent failures. Always refer to the wiring diagram for accurate troubleshooting, ensuring the relay functions as intended in the circuit.

Identifying and Fixing Wiring Errors

Wiring errors in 11-pin relays can lead to malfunctioning circuits, making troubleshooting essential. Start by visually inspecting the connections for loose wires, incorrect pin assignments, or damaged insulation. Use a multimeter to test continuity and voltage levels across the pins, ensuring they match the wiring diagram. Common issues include misaligned pins, reversed polarity, or short circuits. Verify the control and power circuits are isolated and properly connected. If the relay fails to activate, check the coil voltage and ensure the control signal is present. For intermittent operation, inspect for faulty ground connections or overheating. Consult the 11-pin relay wiring diagram to confirm pin functions and correct any mismatches. Fixing errors often involves rewiring connections, replacing blown fuses, or adjusting the control logic. Proper troubleshooting ensures reliable operation and prevents further damage to the system.

- Check for loose or corroded connections;

- Verify pin assignments against the wiring diagram.

- Test for short circuits or open circuits.

Safety Precautions and Best Practices

Always disconnect power before wiring. Use insulated tools and wear protective gear. Ensure proper grounding to prevent voltage spikes. Follow manufacturer guidelines for secure relay installation and optimal performance.

Safety Tips for Handling Relays

When working with 11-pin relays, always prioritize safety to avoid electrical shocks or damage. Ensure the power supply is disconnected before handling the relay to prevent live circuits. Use insulated tools to minimize the risk of electrical contact. Avoid touching pins or terminal connections to prevent static discharge, which can damage sensitive components. Wear protective eyewear and gloves to safeguard against accidental sparks or debris. Mount relays securely to prevent vibration-induced failures. Never force connectors or wires, as this can cause permanent damage. Keep the workspace well-lit and clear of flammable materials. Follow the manufacturer’s guidelines for voltage and current ratings to ensure safe operation. Regularly inspect the relay and wiring for signs of wear or overheating. Always test the circuit at low power first to identify potential issues before full operation. Proper handling and adherence to safety protocols are essential for reliable performance and longevity of the relay system.

Best Practices for Installation

When installing an 11-pin relay, ensure proper grounding to prevent electrical noise and interference. Use a high-quality wiring harness and secure connections to avoid loose contacts. Always refer to the wiring diagram specific to your relay model to match pin functions correctly. Mount the relay in a well-ventilated area to prevent overheating. Apply a thin layer of dielectric grease to connectors for corrosion protection. Test the circuit before powering up to verify continuity and functionality. Avoid overloading the relay with excessive current, as this can damage internal contacts. Use appropriate tools to crimp and solder wires for reliable connections. Ensure the relay is compatible with your system’s voltage and current requirements. Regularly inspect wiring for signs of wear or damage. Follow safety protocols, such as disconnecting power before working on the circuit. These practices ensure a safe, efficient, and durable installation.

Resources and Further Reading

For detailed 11-pin relay wiring diagrams, explore technical forums, manufacturer websites, and PDF databases. Trusted sources include datasheets from relay manufacturers and tutorials on automotive electronics. Always verify the source for accuracy.

Where to Find Reliable 11-Pin Relay Diagrams

Reliable 11-pin relay wiring diagrams can be sourced from various technical resources. The internet offers a wealth of information, including downloadable PDFs. Reputable manufacturers often provide detailed wiring diagrams specific to their relay models, which can be found on their official websites. Additionally, technical forums and electronics communities, such as All About Circuits or Electronics Tutorials, frequently share schematics and guides for 11-pin relays. Automotive repair websites and industrial automation platforms also host comprehensive resources. For specific applications, such as interlocking wiring or circuit diagrams, referring to technical articles or eBooks on platforms like ResearchGate or IEEE Xplore can be beneficial. Always ensure the diagrams are from credible sources to guarantee accuracy and safety in your wiring projects.

Recommended Tools for Wiring Projects

When working with 11-pin relay wiring diagrams, having the right tools is essential for accuracy and safety. A multimeter is crucial for testing voltage, current, and continuity in circuits. Wire strippers and crimpers are necessary for preparing and securing connections. Pliers and screwdrivers are handy for tightening terminals. A soldering iron and flux can ensure durable joints, though they may not always be required. Insulated tools prevent accidental shorts, while a wiring harness kit keeps connections organized. For more complex setups, a relay socket tester can verify pin functionality. Safety glasses and gloves are vital for protection. Using high-quality tools ensures reliable connections and minimizes risks of electrical hazards. Always refer to the manufacturer’s guidelines for specific tool recommendations tailored to your project. Proper tools not only simplify the process but also ensure long-term reliability of the wiring system.

Understanding 11-pin relay wiring diagrams is essential for safe and efficient circuit design. Proper connections ensure reliability, while incorrect wiring can lead to system failures or safety hazards.

Understanding 11-pin relay wiring diagrams is essential for proper circuit installation and functionality. These diagrams provide a clear visual representation of pin configurations, ensuring accurate connections for control and power circuits. By following the diagram, technicians can identify the correct pins for voltage supply, coil activation, and output switching. This prevents wiring errors, which are common causes of relay failures. Additionally, the diagrams highlight safety practices, such as proper grounding and voltage handling. They are particularly useful in automotive and industrial automation, where relays control multiple devices. Regular testing and inspection of relay circuits are recommended to maintain system reliability. Always refer to manufacturer-specific diagrams for precise instructions, as pin functions may vary between models. Properly interpreting these diagrams ensures efficient and safe relay operation in any application.

Final Thoughts on Working with 11-Pin Relays

Mastery of 11-pin relay wiring requires patience and attention to detail. These relays are versatile, used in automotive and industrial systems for controlling high-power circuits. Always refer to a reliable wiring diagram to ensure proper connections. Start by understanding the pin functions and how they interact in your specific application. Practice on a test circuit before integrating into a live system. Safety is paramount; always disconnect power before working. Use appropriate tools to avoid damage. Troubleshooting is easier with a clear diagram. Common issues include incorrect pin connections or faulty components. Regularly inspect and maintain relays to prevent failures. With practice, you’ll gain confidence in designing and troubleshooting complex relay circuits. Remember, precision and adherence to diagrams are key to success in any wiring project. Keep learning and refining your skills for optimal results.